Foundry

Melting

250kW Medium frequency coreless induction furnace with one control panel and 2 Nos of 500 kgs crucibles. With Tap Out time of 70 Minutes, we have a production capacity of 4500 Heats per Year, which makes our Annual Good casting capacity of 1200 Tonnes considering two shifts only.

Moulding

Moulding facility with pneumatic ramming for C02 moulding. No bake moulding (Alcade) , and Shell moulding , outside sources for cold box cores is also set.

Fettling

Fettling setup with pneumatic grinders , We also have a 600A welding rectifier and 400A welding transformer. Our welder and welding procedure are qualified as per ASME Sec. IX of Boiler & Pressure Vessel code.

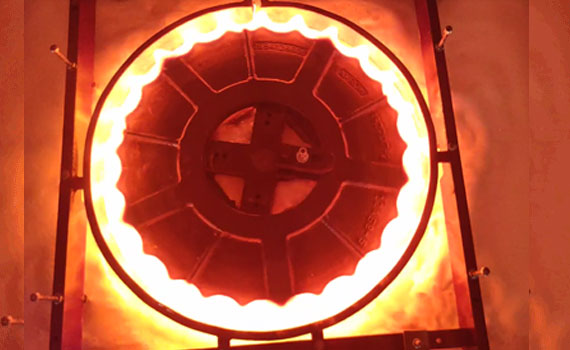

Induction Hardning

Special Purpose IGBT based precision controlled, 450 KW, Medium Frequency Single shot in house Induction hardening machine for Sprockets and Idlers.

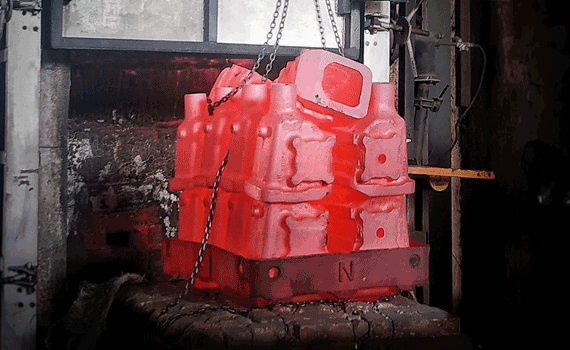

Heat Treatment

2 Nos Gas fired heat treatment furnace with table size 1200 X 900 X 1000 mm and 1200 x 2000 x 650 mm. Water quenching facility of 18,000 ltr.

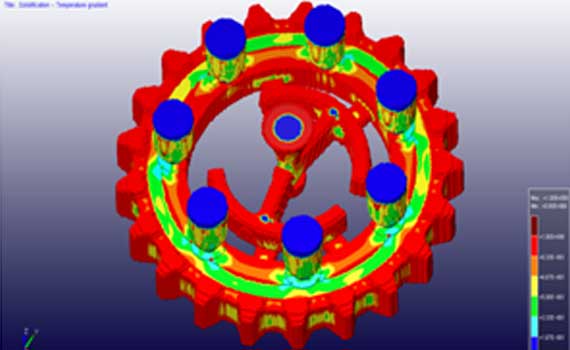

Design & Development

Solidwork for the 2D And 3D modeling and Z-Cast Simulation Software to Aid process design.

Pattern Shop

Pattern making from wood, aluminium, Thermocole, Cast Iron is being outsourced from a reliable facility. We have an in-house facility for match plating, layout inspection and pattern repairs.

Software

We have specially used ERP Software System.

Quality

Spectrometer

The facility includes Bruker quantron make, 19 elements Optical Emission Spectrometer with low alloy and high alloy CRM samples for daily setup of spectro.

Hardness Testing

- Vickers Hardness testing

- Rockwell Hardnes testing

- Brinell Hardness testing

- Poldy Hardness Testing

Mechanical Testing

- UTM

Impact Testing

- Capacity

Sand Testing Facility

- GCS Machine

- Sieve Shaker

- Clay Content analysis equipement

- Moisture % analysis equipement

NDT Testing

NDT facilities like UT, MPI, DT With qualified technicians available in house. RT is outsource.